Aluminium Profile

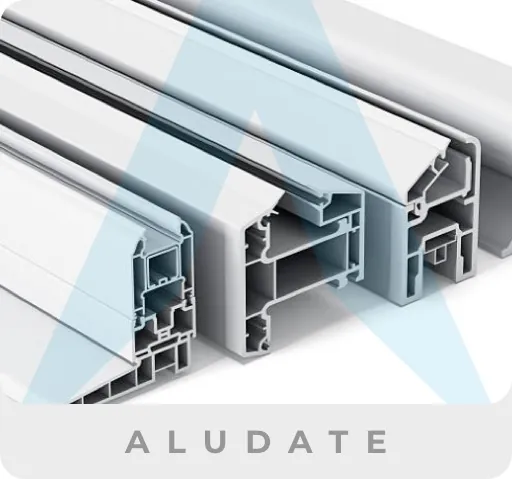

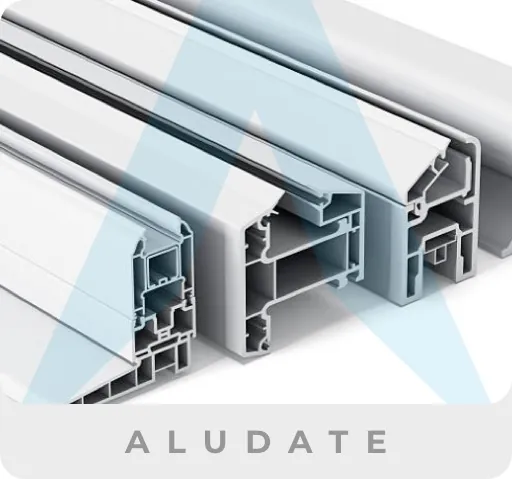

High-performance aluminium extrusion profiles from primary billets for architectural, industrial, and specialty applications worldwide.

Overview

Specifications

At Aludate, quality begins at the source. We exclusively utilize primary aluminium billets as the starting material for our high-quality extruded products. This strict material selection guarantees sustainable quality and perfect surface consistency, especially for anodised and powder-coated finishes.

The extrusion process is executed with precision: billets are heated to optimal temperatures (approx. 450°C to 500°C) and forced under high pressure through specific dies to achieve the desired cross-section. Following extrusion, the profiles undergo stretching and controlled thermal aging in special furnaces to ensure the necessary mechanical strength and durability.

We supply premium quality profiles using a wide range of standard and special alloys to meet your specific project requirements. All physical and chemical specifications are strictly maintained according to international standards. Our standard alloy portfolio includes the 6000 Series (6060, 6061, 6063, 6005, 6082, 6463) ideal for architectural and structural use, and the 1000 Series (1050) for high purity electrical and chemical applications. Custom alloy compositions are available upon request.

Features

Key Features

Advantages

Key Advantages

High-performance aluminium extrusion profiles from primary billets for architectural, industrial, and specialty applications worldwide.

Specifications

Technical Specifications

Use Cases

product_detail.applications

Explore Options

Complete Product Catalog

Interested in This Product?

Contact our engineering team for technical specifications, pricing, and custom solutions.