Aluminium Composite Panel (ACP)

The skin of modern architecture — two coil-coated aluminium sheets fusion-bonded to a core providing the perfect balance of lightweight construction and superior rigidity.

Overview

Specifications

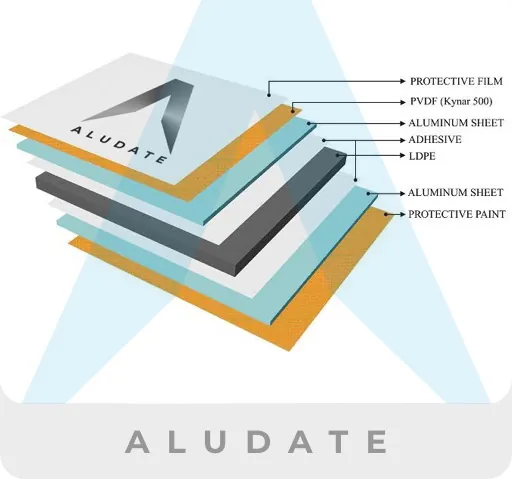

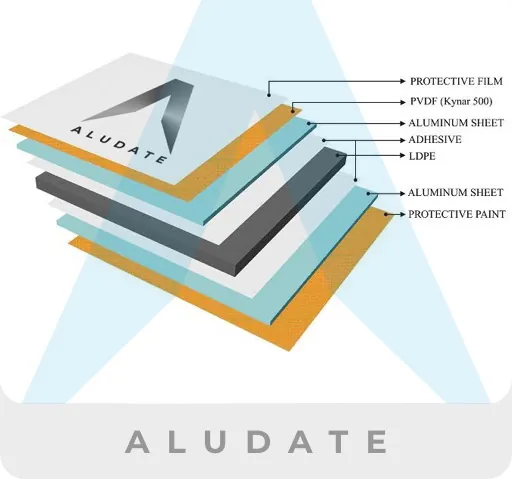

Aludate Aluminium Composite Panels (ACP) act as the skin of modern architecture. Comprising two coil-coated aluminium sheets fusion-bonded to a polyethylene or mineral-filled core, our panels offer the perfect balance of lightweight construction and superior rigidity. They are engineered to provide architecturally unique design solutions for both exterior facades and interior decoration.

Our ACP products are designed to meet rigorous construction standards with fire safety options including standard PE core or Fire-Resistant (FR) cores (Class B1 and Non-Combustible A2) for high-rise safety. Panels are coated with high-performance PVDF (Kynar 500) or Nano-PVDF paints, ensuring resistance to UV rays, corrosion, and fading for decades. The panels are easily folded, bent, and curved, allowing for complex architectural shapes.

We supply panels with high-grade alloy skins (3003, 3105, 5005 Series in H24/H26 tempers) to ensure flat surfaces and structural integrity. Standard panel thickness is 3mm and 4mm (up to 6mm available), with aluminium skin thickness from 0.21mm to 0.50mm. Coating types include PVDF, Polyester (PE), and Anodized looks.

Features

Key Features

Advantages

Key Advantages

The skin of modern architecture — two coil-coated aluminium sheets fusion-bonded to a core providing the perfect balance of lightweight construction and superior rigidity.

Specifications

Technical Specifications

Use Cases

product_detail.applications

Interested in This Product?

Contact our engineering team for technical specifications, pricing, and custom solutions.