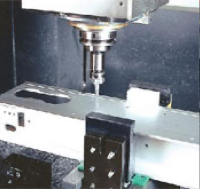

Aluminium Profile Machining Centre

The advancing globalisation is placing companies in Europe under more and more pressure with regards to costs. In order to continue to be economically successful under ever changing conditions, you need reliable and professional partners.

Aludate& Metal components is your answer to this challenge. Our offering ranges from machining on ultra-modern CNC machines, through welding and punching right up to the complete assembly of whole modules – all, of course, packed & optimally in line with your instructions.

We produce for you in a low-cost country with highly trained specialist personnel on machines of the latest generation. Thanks to this modern, high-performance machine park logically arranged over approx. 3000 m² of hall area, we guarantee a perfectly organised and hence highly economical production process. This ensures & consistently high quality, short order handling times and reduces production costs.

Our partners are thus able to concentrate on their key business again. Expensive overtime, high investments, production risks and unnecessarily tied-up capital are now a thing of the past.

Capability of sensitive angular cutting in both X axis and Y axis,

Angular and 90 -degree cutting in the double head cuttig unit,

Tube and rod-plate cutting line for automotive sector,

Punching, combining, canal opening in hydraulic and eccentric presses,

tube and rod-plate cutting line for automotive

Thread opening, countersinking,

Processing capability at 5 axisin the sensitive tolerances in CNC work centers,

Emery process on the profile cutting surfaces,

CNC tube beding,

CNC profile beding,

Welding ,rivet, pressing and other applications for various bindig processes,

TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) velding by WATC ( TÜV Nord Accreditation

Company-Welder Approval Test Certificate) cetified personnel. Welding procces and method are certified by the WPS (Welding procedure specification) and WPAR (Welding procedure Approval Record) certificates by Tüv/Nord Company.

CNC lathe work for obtainig high precise diameter tolerances.

Chamfering.

Folio coating for protecting the profile surfaces

Also semi-finished and /or finished assemblies are made with sub-assembly lines for various applications.

New incoming projects are taken up with a great sensitivity by our specialized staff i accordance with your demands and alternative suggestions are offered in accodance with your needs. We provide you all kinds of support and assistance on your product designs.

Main sectors which supply as part manufacturing could be listed as, Electronic home Appliances sector, Automotive sector, Electric –Electronics sector, Machine Manufacturing sector, Furniture sector, Construction sector.